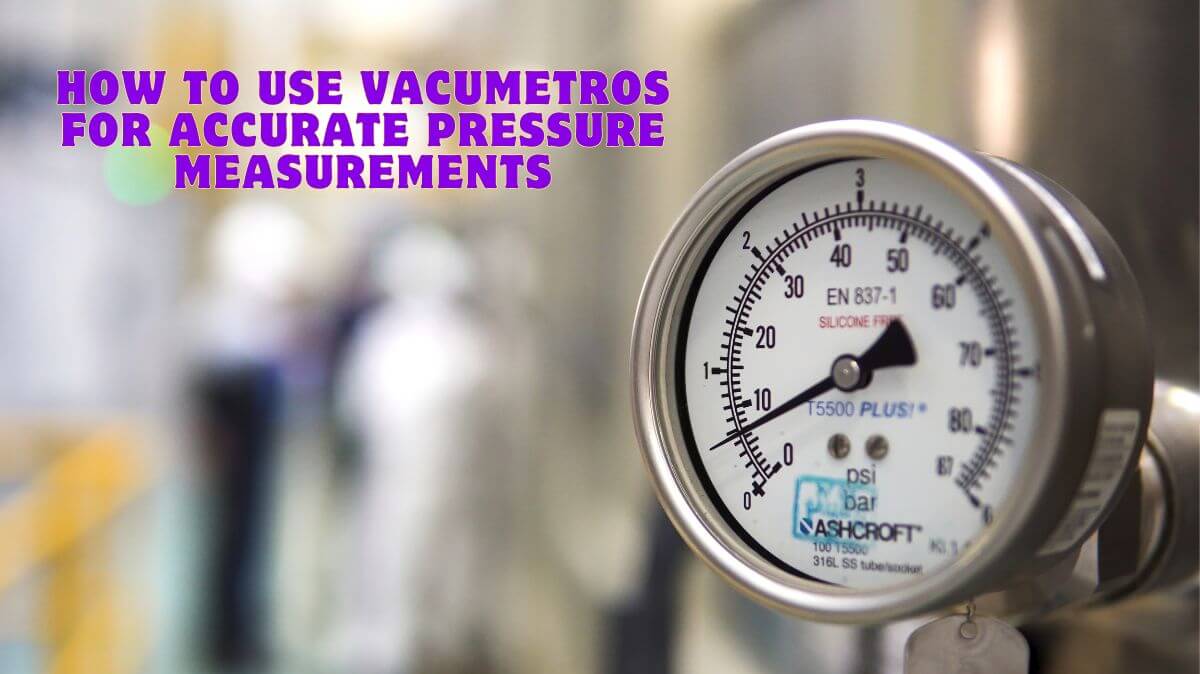

Introduction to Vacumetros

When it comes to measuring pressure, precision is key. Whether you’re a scientist in a lab or a technician in the field, having reliable tools can make all the difference. Enter vacumetros—your go-to devices for accurate pressure measurements in vacuum environments. These instruments not only allow you to gauge how much pressure is present but also help ensure that your processes run smoothly and efficiently.

In this post, we’ll dive into everything you need to know about vacumetros. From understanding measurement units to exploring different types available on the market today, let’s embark on this journey together and unlock the potential of these essential tools!

Understanding Pressure Measurement Units

Pressure measurement units can be a bit confusing. Various systems exist to quantify pressure, and understanding them is essential for accurate readings.

The most common unit is the pascal (Pa), which measures force per square meter. Kilopascals (kPa) are often used in practical applications, making it easier to interpret higher pressures.

Another widely recognized unit is the bar, where one bar equals 100 kPa. This scale offers a clearer perspective when dealing with atmospheric or industrial pressures.

You may also encounter inches of mercury (inHg). This unit relates directly to measuring vacuum levels. It reflects how high mercury would rise in a tube due to atmospheric pressure.

Knowing these units helps you select the right vacumetro for your needs and ensures precise measurements throughout various processes.

Types of Vacumetros and Their Uses

Vacumetros come in various types, each designed for specific applications. The most common type is the analog vacumetro. These devices utilize a mechanical dial to show pressure levels. They are easy to read and widely used in laboratories.

Digital vacumetros offer enhanced accuracy and readability. With their electronic displays, they can provide real-time data analysis. This makes them ideal for high-precision tasks in industries like pharmaceuticals.

Another popular option is the piezoresistive vacumetro. These instruments measure pressure by detecting changes in resistance within a material under stress. They are often employed in environments where temperature variations occur frequently.

For more rugged applications, you might encounter capacitive vacumetros. Their robust design allows them to withstand extreme conditions while delivering reliable readings.

Each type has unique features tailored to different industrial needs, ensuring effective vacuum measurements across diverse settings.

Tips for Accurate Pressure Measurements with a Vacumetro

When using a vacumetro, calibration is key. Always ensure your device is calibrated according to the manufacturer’s specifications before taking measurements. This step minimizes errors and enhances accuracy.

Next, consider temperature effects. Changes in temperature can impact pressure readings. Aim for a stable environment where fluctuations are minimized.

Positioning matters too. Ensure the vacumetro is installed properly within the system, avoiding any bends or kinks in tubing that could interfere with accurate readings.

Regular maintenance cannot be overlooked. Clean your vacumetro periodically and inspect it for any signs of wear or damage. A well-maintained instrument will provide more reliable results.

Take multiple readings when possible. Averaging these values can help account for any random discrepancies and lead to a clearer understanding of pressure levels in your application.

Also Read: Mastering Tratear: From Fundamentals to Advanced Practice

Common Mistakes to Avoid When Using a Vacumetro

When using a vacumetro, precision is key. One common mistake is placing the device in an incorrect position. Ensure that it’s aligned correctly for accurate readings.

Another frequent error involves ignoring temperature variations. Changes can affect pressure measurements, so always consider your working environment.

Failing to calibrate the vacumetro regularly also leads to inaccuracies. Calibration ensures that you obtain reliable results every time you measure.

Many users forget about proper maintenance, which is crucial for longevity and performance. Regularly clean and inspect your equipment to avoid malfunctions.

Don’t neglect reading the manual carefully! Each model may have specific instructions that could save you from errors down the line. Taking these precautions will help achieve optimal accuracy in your measurements.

Applications of Vacumetros in Various Industries

Vacumetros play a crucial role across diverse industries. In the pharmaceutical sector, precise vacuum measurements ensure optimal production conditions for medications. This precision is vital to maintain drug efficacy and safety.

In food processing, vacumetros help control packaging environments. By measuring pressure accurately, manufacturers can extend shelf life while maintaining product quality.

The automotive industry benefits from these devices during testing phases. Ensuring proper vacuum levels in components like brake systems enhances vehicle performance and safety.

Furthermore, in research laboratories, vacumetros are essential for experiments that require controlled atmospheric conditions. Researchers rely on accurate readings to achieve reliable results.

The semiconductor manufacturing process also utilizes vacumetros extensively. They monitor vacuum levels critical for creating high-quality electronic components effectively.

Conclusion

Vacumetros are essential tools for precise pressure measurements across various industries. Understanding how to use them correctly can greatly enhance your work’s accuracy and efficiency. From knowing the different types available to mastering the nuances of measurement units, each aspect plays a crucial role in achieving reliable results.

By following best practices and avoiding common pitfalls, you can ensure that your readings are spot on every time. Whether you’re working in manufacturing, research laboratories, or HVAC systems, vacumetros provide invaluable data that help maintain standards and improve outcomes.

As technology continues to advance, keeping up with the latest developments in vacumetro usage will only further empower professionals seeking accurate measurements. Embracing this knowledge opens doors for innovation and enhanced performance in any project requiring vacuum pressure monitoring.